Our Product

Overview

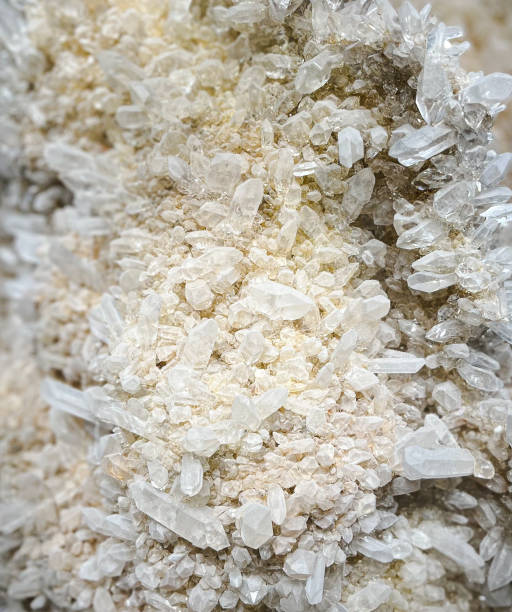

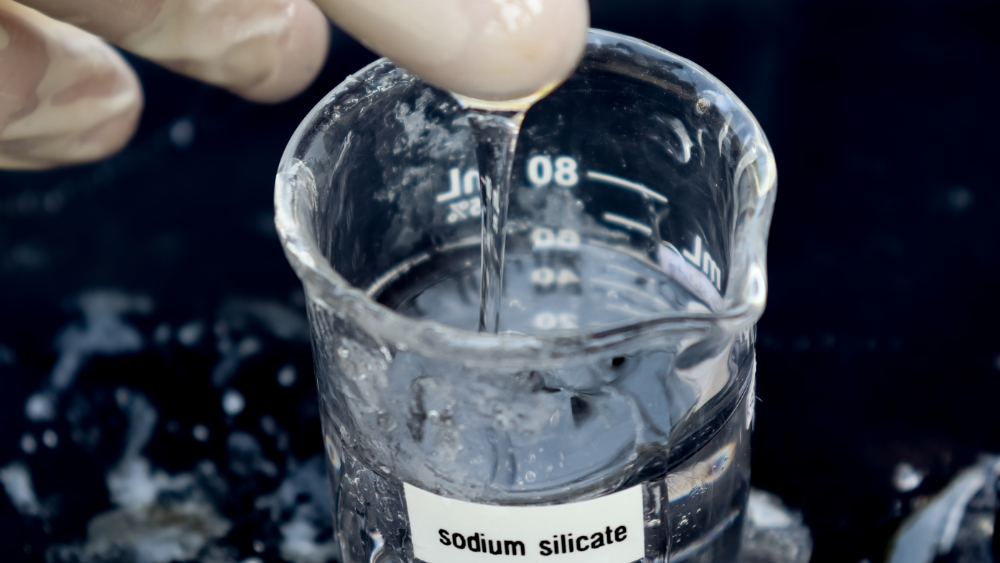

Sodium silicate is an inorganic compound containing sodium oxide and silica, also known as water glass or soluble glass or Sodium metasilicate. It is basic in nature, white to greenish opaque crystals, highly soluble in water with high melting point. This alkaline substance is available as a nearly colorless, glass-like powder, or as a syrup-like liquid when mixed with water and heated under pressure. The viscosity of this compound depends on the ratios of silica and sodium oxide used. Sodium silicate has a variety of industrial, agricultural and manufacturing uses. It is stable in neutral and alkaline solutions, in acidic solutions, the anion silicate reacts with hydrogen ions to form silicic acid. Silica gel a well known desiccant is a hard and glassy substance is formed by heating and roasting of sodium silicate.

Sodium Silicate (Na2SiO3) is prepared by melting sand and Sodium Carbonate (Soda Ash). Its wide range of applications includes the manufacturing of Detergents, Silica Gel, Card-board and Paper, Textiles, Paints, Adhesives, Pottery and Sanitary ware, Refractories, Foundry and Wood Processing Industries. The liquid form of sodium silicate is used in the manufacturing of additives because of its low cost, non toxic and environmentally friendly nature.

Application

Here are some common applications of sodium silicate:

Detergent and Cleaning Products: Sodium silicate is used in the manufacturing of detergents and cleaning products. It helps to stabilize and control the viscosity of detergents, and it can also prevent soil redeposition on fabrics during the washing process.

Paper and Cardboard Production: Sodium silicate is used in paper and cardboard production as a binder and coating. It can improve the water resistance and strength of paper products, making them more durable.

Cement and Concrete Industry: Sodium silicate can be used as an additive in cement and concrete formulations to improve their properties. It can enhance the early strength development of cement and contribute to the stabilization of soil in construction projects.

Adhesive and Sealant Formulations: Sodium silicate is used in the formulation of adhesives and sealants, particularly in applications that require heat resistance and good adhesion to porous surfaces, such as wood, concrete, and ceramics.

Textile Industry: Sodium silicate is used in the textile industry for dyeing and printing processes. It can act as a stabilizer for dyes and as a resist agent to create patterns on fabrics.

Fireproofing and Heat Insulation: Sodium silicate is used as a fireproofing agent and heat insulator. When applied to materials like wood, fabric, or paper, it can provide a protective barrier against flames and high temperatures.

Foundry and Metal Casting: Sodium silicate is used in foundry operations as a binder in the production of molds and cores for metal casting. It can improve mold strength and dimensional stability.

Water Treatment: Sodium silicate is used in water treatment processes to control corrosion and scale formation in industrial equipment and pipelines.

Automotive and Machinery Repair: Sodium silicate-based solutions, often referred to as “liquid glass,” have been used as temporary engine block sealants in emergency situations to seal minor coolant leaks.

Art and Craft: Sodium silicate is sometimes used in art and craft projects as a sealant, adhesive, or even as a strengthening agent for delicate materials like eggshells.

Spesification

| Property | Specification | Applications |

|---|---|---|

| Chemical Formula | Na2O·mSiO2 (m varies) | Detergents, Cleaning Products, Adhesives |

| Appearance | Liquid, Solid (Powder) | Paper Production, Cement Industry |

| pH (1% solution) | ~11 – 12 | Concrete Additive, Textile Dyeing |

| Solubility | Soluble in Water | Fireproofing, Heat Insulation |

| Viscosity | Variable | Foundry Casting, Water Treatment |

| Binding Properties | Adhesive and Binding Agent | Automotive Repair (Temporary Sealant) |

| Strength | Varies | Art and Craft Projects |